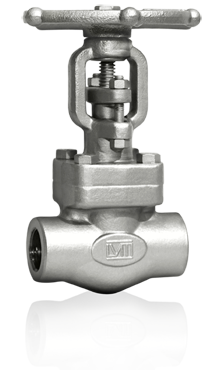

Our gate valves are of manifold tunrnings. The pitch orifice is locked by a solid leantsurfaced wedge between the supports.

Suitable for opening or locking duties, but inappropriate for flow cheeking; straight pitch with minimal load decrease.

Use: General duties, resins, oil and gas, steam and fluids of different levels of viscosity.

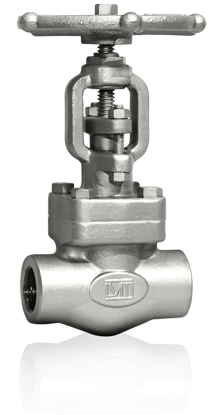

Our globe valves are of manifold turnings. Locking occurs by means of a conical disc which obtrudes the fluid flowing through the support.

Suitable for checking duties. Liquid or gaseous flow. Moderate load decrease.

Use: General duties, liquid, steam and gas.

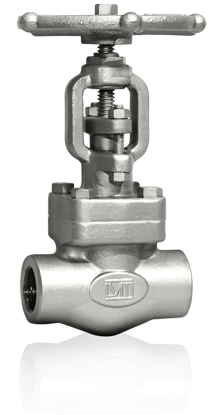

Our needle valves are of manifold turnings. Locking occurs by means of a conical disc in the valve rod. Which obtrudes the fluid flowing through the pitch orifice.

Suitable for a fine checking of fluids; high load decrease.

Use: General duties, liquid, steam and gas.

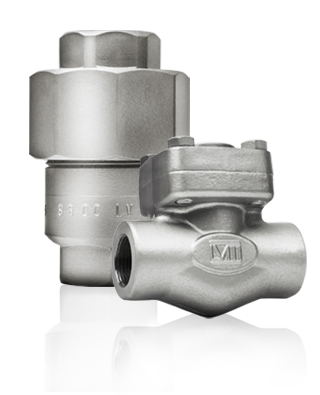

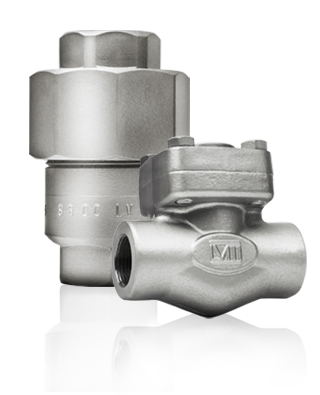

Our check valves are automatic valves, independent of external control, and operate according to the flow or preassure direction in the pipe system.

Our check valves include ball, piston and swing types, which allow fluid flowing in a only direction.

Horizontal - ball or piston: Set only a horizontal position. Moderate load decrease.

Lid-top: Set either horizontally or vertically. Very low load decrease.

Vertical - ball: Set only vertically. Moderate load decrease.

Use: Resins, oil, steam and fluids of different levels of viscosity. Inappropriate for drygas dealing.

In the following tables you will be able to check the working pressure and temperature conditions of our products. In case of any concerns the technical department will be at your disposition and will assist and guide you for the correct use and determination of the different materials.

1 MPa = 10 bar = 10.2 Kg/cm2

Forged steel valves, carbon steel and alloy.

| Designation ASTM | A-276 / A-479 | A-582 | A-217 | A-351 | B-164 | Stellite Gr. 6 | ||||

| Gr. 410 | Gr. 420 | Gr. 440C | Gr. 316 | Gr. 416 | Gr. CA15 | Gr. CF8M | monel | |||

| Carbono ??C | % | 0.08 ??0.15 | 0.15 min. | 0.95 ??1.20 | 0.08 màx. | 0.15 màx. | 0.15 máx. | 0.08 máx. | 0.30 máx. | 1.1 |

| Manganeso ??Mn | máx. % | 1.00 | 1.00 | 1.00 | 2.00 | 1.25 | 1.00 | 1.50 | 2.00 | ??/td> |

| Fósforo ??P | máx. % | 0.040 | 0.040 | 0.040 | 0.045 | 0.060 | 0.040 | 0.040 | ??/td> | ??/td> |

| Azufre ??S | máx. % | 0.030 | 0.030 | 0.030 | 0.030 | 0.15 mín. | 0.040 | 0.040 | 0.024 | - |

| Silicio ??Si | máx. % | 1.00 | 1.00 | 1.00 | 1.00 | 1.00 | 1.50 | 1.50 | 0.50 | ??/td> |

| Cromo ??Cr | % | 11.5??3.5 | 12.0??4.0 | 16.0??8.0 | 16.0??8.0 | 12.0??4.0 | 11.5-14.0 | 18.0-21.0 | ?? | 28.0 |

| Níquiel ??Ni | % | ??/td> | ??/td> | ??/td> | 10.0??4.0 | ??/td> | 1.00 máx. | 9.0-12.0 | 63.0 mín. | ??/td> |

| Molibdeno ??Mo | % | ??/td> | ??/td> | 0.75 máx | 2.0??.0 | ??/td> | 0.50 máx. | 2.0-3.0 | ??/td> | ??/td> |

| Wolframio ??W | % | ??/td> | ??/td> | ??/td> | ??/td> | ??/td> | ??/td> | ??/td> | ??/td> | 4.0 |

| Cobalto ??Co | % | ??/td> | ??/td> | ??/td> | ??/td> | ??/td> | ??/td> | ??/td> | ??/td> | Resto |

| Cobre ??Cu | % | ??/td> | ??/td> | ??/td> | ??/td> | ??/td> | ??/td> | ??/td> | 28.0??4.0 | ??/td> |

| Other | % | ??/td> | ??/td> | ??/td> | ??/td> | ??/td> | ??/td> | - | Fe: 2.5 máx. | ??/td> |

| Parts Valve type |

Body and Bonnet | Stem | Seeal | Disc, Piston, swing or Wedge |

Ball | Spiral Wound Gasket | Flat Metal Gasket | Packing |

| Gate and Globe | A-350 LF2 A-105 A-182 F5 A-182 F9 A-182 F11 A-182 F316L |

Gr. 410 Gr. 316 B-164 |

Gr. 410 Gr. 410 + HF Gr. 316 Gr. 316 + HF B-164 |

Gr. 410 Gr. 410 + HF Gr. 316 Gr. 316 + HF B-164 |

??/td> | 316/Grafito 316/PTFE Monel/PTFE Monel/Grafito |

??/td> | Grafito PTFE |

| Horizontal Check | A-350 LF2 A-105 A-182 F5 A-182 F9 A-182 F11 A-182 F316L |

??/td> | Gr. 410 Gr. 410 + HF Gr. 316 Gr. 316 + HF B-164 |

Gr. 410 Gr. 410 + HF Gr. 316 Gr. 316 + HF B-164 |

Gr. 420/440 C Gr. 316 B-164 |

316/Grafito 316/PTFE Monel/PTFE Monel/Grafito |

??/td> | ??/td> |

| Check swing type | A-350 LF2 A-105 A-182 F5 A-182 F9 A-182 F11 A-182 F316L |

??/td> | Gr. 410 Gr. 410 + HF Gr. 316 Gr. 316 + HF B-164 |

Gr. 410 Gr. 410 + HF Gr. 316 Gr. 316 + HF B-164 |

?? | 316/Grafito 316/PTFE Monel/PTFE Monel/Grafito |

??/td> | ??/td> |

| Vertical Check | A-350 LF2 A-105 A-182 F316L |

??/td> | Gr. 410 Gr. 410 + HF Gr. 316 Gr. 316 + HF B-164 |

??/td> | Gr. 420/440 C Gr. 316 B-164 |

??/td> | Cobre Gr. 316 |

??/td> |

| Needle | A-350 LF2 A-105 A-182 F316L |

Gr. 420 Gr. 420 + HF Gr. 316 Gr. 316 + HF |

Integral | ??/td> | ??/td> | ??/td> | Cobre Gr. 316 |

Grafito PTFE |

HF: Hard face with stellite No 6 or similar.

Meet the conversion to inches of our valves in the table below:

| Measurement valves | |

| In inches | In milimeters |

| ¼ | 6.350 |

| 3/8 | 9.525 |

| ½ | 12.700 |

| 3/4 | 19.050 |

| 1 | 25.400 |

| 1¼ | 31.750 |

| 1½ | 38.100 |

| 2 | 50.800 |